Meet ER-FLEX

Experience ER-FLEX: agile, stable, and easy to deploy. Available in four models, each combining a MiR250 mobile base (from Mobile Industrial Robots) with a range of Universal Robots arms designed to suit various applications and payloads. All models offer an optional ESD coating for electro-sensitive environments.

Arm Options

ER-FLEX 250-7e

For applications that require a small-sized cobot with sufficient reach and payload, the UR7e will help you perform precise, meticulous tasks and the mobility of the robot gives you similar possibilities as that of a human worker.

Coating

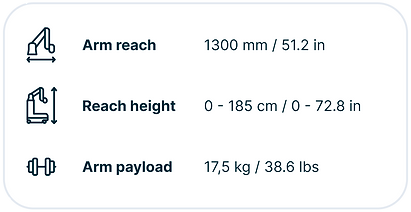

Specifications

Robot Safety Measures

-

Proximity sensors scan the area around the robot

-

Laser scanners detect distant objects

-

3D cameras can detect objects within a field of view up to 1.8 m in height and 1.2 m in distance

-

Force sensors stop the arm if counter pressure is detected

Robot Communication

-

LED lights show the robot's status

-

Audio signals or voice messages (optional) indicate the robot's status

Programming

-

Robot arm returns to a 'safe home' position when the mobile unit moves

-

Speed is reduced when an object is detected nearby

ER-ABILITY

ER-ABILITY software provides an easy interface for programming and operating ER-FLEX, with features like:

-

Simple programming interface

-

Vision system for precise localization

-

QR and barcode reading

-

Communication with IT systems via REST or OPC-UA

Safety

ER-FLEX ensures maximum safety when working alongside humans, designed to prevent tipping even with heavy payloads.

It features two E-stops, an expandable safety system, and power/force limitation to control speed. Safety zones can restrict arm movement.

Equipped with two SICK laser scanners for 360-degree vision, it detects obstacles and people. ISO 13849 certified (Performance Level D), plus two 3D cameras and eight proximity sensors for added safety.

For safety and precision, the robot arm remains securely stationary while the mobile base moves. This design prioritizes safe operation around people — eliminating the need for screens or fences.

Accessories

The standard ER-FLEX model features a low front module for transporting and handling parts. For handling smaller items, a high top module is also available. Accessories include charging stations and 3D markers.

For custom front modules, feel free to contact us.

Full autonomy and lights out production

Smart production layouts let ER-FLEX charge while working, enabling 24/7 efficiency. It can run autonomously or handle large batches at night while employees manage smaller, varied tasks. Flexible and adaptable, it suits endless possibilities.